Fabrics

ASADA Normal and Calendered stainless steel wire cloth

Standard BS-Series & SS-Series BS-Standard High Tensile Fine。 Calendered Screen Type-CL Calender Process。 Hardmesh Ms-Series High Yield Strength Fine Mesh。 Supermesh HS-Series Super High Tensile & Low Elongation。 Black Screen Type-BLK Screen with Black Surface Treatment。

Characteristic:

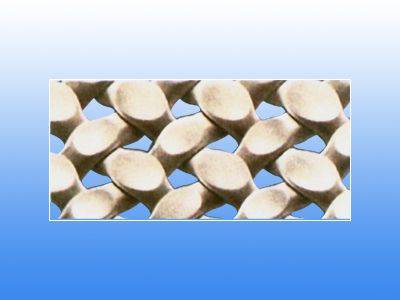

Standard BS-Series & SS-Series

BS-Standard High Tensile Fine

Mesh Specification

Longtime seller in screen-printing and sieving applications From multi-layer printing,such as MLCC ceramic capacitors,to industrial sieving/test sieving applications,this is our principal product used in a wide range of fields for over 40 years,we are using BS-wires that have a 25% higher tensile strength compared to conrentional stainless steel 304(SS-wires)。

Calendered Screen Type-CL

Calender Process

Asada s unique technology achieves thin mesh with outstanding Thickness uniformity and flat-lying characteristics。

This process enables mesh to achieve thinner thickness that is not Possible with a regular woven screen。Our unique process technology Enhanced thickness uniformity/flat-lying characteristics of mesh to Achieve smoother squeegeeing,This product shows its capabilities in Superior edge definition,and printing dimensional accuracy。

Hardmesh Ms-Series

High Yield Strength Fine Mesh

For screen-printing which requires a high-level of dimension accuracy and printing. In order to respond to the needd of higher strength and lower longation in the screen-printing field,we have newly developed this fine mesh,By using material which has 30-40% better tensile strength compared to conventional Bs- & SS-STANDARD,plastic deformation will not occur up to the breaking point。MS-Hardmesh is most suited for printing coil and hybrid IC patterns,which demand high-levels of dimension accuracy and printing durability。

Supermesh HS-Series

Super High Tensile & Low Elongation

Fine Mesh Specification

High open area mesh。Printing high viscosity paste at low printing pressures is possible。

This mesh uses a wire which has 3 times higher tensile strength compared to BS-&SS-STANDARD and extremely low elongation rate of 3-5%,which open area ratics exceeding 60%。Thin wired diameter and high open area ratio provide exceptional paste releasing capabilities,making it possible to print with high viscosity paste with low printing pressure 。This product shows extraordinary performance in printing that requires fine patterns and dimensional accuracy。HS-Supermesh is used to apply phosphors on Plasma Display Panel (PDP),and most recently, it is also drawing attention for sieving applications。

Black Screen Type-BLK

Screen with Black Surface Treatment

Sharp line edge definition with remarkable resolution。

By treating the surface of the mesh by marking it black,it minimizes random reflection of light during exposure,and develops sharper pattern edges of the film /photo mask。Regardless of the quantity of exposures,it comes out high definition images,and especially ,shows its capability at the fine line pattern of below 50um,Moreover ,it reduces smudges of paste to allow continuous printing,and its performance in printing durability is also largely increased due to an Improvement in adhesion of emulsion。It is an Asada Mesh unique product which efficiently achieves high precision pattern printing。