Stencil Making Equipments

G-Coat 411

The G-COAT 411 provides safe and rapid coating on both sides, in any desired thickness and quality

Particular features

■ Safe reproductibility of the coating results guaranteed for direct coating process wet-on-wet (tolerance +/- 1μ)

■ By means of the input keyboard on the front panel, the frame profile height and the wiping process can be easily adjusted to the respective screen frame size.

■ Either millimeters or inches can be selected as a measuring unit.

■ The separate control of both coating troughs allows to coat the mesh from the squeegee side, from the printing side or from both sides.

■ The contact pressure of the coating troughs on the mesh can be adjusted separately for both sides.

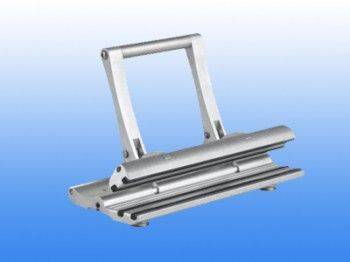

■ A screen frame clamping device with pneumatic positioning on top and at the bottom allows to fasten the screen frame. Control via a foot-operated pedal.

■ Extremely silent running characteristics of the coating carriage and of the hot-air dryer, due to the use of special steel strips with special synthetic guideways.

■ Due to the use of trapezoidal toothed belts, the drive unit is practically maintenance-free.

■ A monitoring of the compressed air by means of a sensor and a blocking valve at the entry prevents any compressed air malfunctions which might have a negative effect on the coating result.

|

Screen frame size

|

SB Screen frame width

|

mm/inch

|

1000-3000 39"-118"

|

|

|

SH Screen frame length

|

mm/inch

|

1250-5000 49"-275"

|

|

|

Frame profile height

|

mm/inch

|

30-195 1"-8"

|

|

|

Frame profile thickness

|

mm/inch

|

10- 60 0.3"-2"

|

|

Index of options

|

R.T.P.Z.

|

|

|

|

Overall size

|

Total width

|

mm/inch

|

SB+1150/45“

|

|

|

Total height

|

mm/inch

|

SH + 770/30“

|

|

|

Total depth

|

mm/inch

|

580/23“

|

|

Energy supply

|

Nominal voltage Volt

|

V

|

3x400 + N + PE

|

|

(Depending onthe heating capacity)

|

3x220PE

|

||

|

|

Fuse protection

|

A

|

10-25

|

|

|

Capacity

|

Kw

|

1-12

|

|

Frequency Hz 50/60

|

|

|

|

|

Compressed air

|

Connection value

|

bar

|

6

|

|

|

Air consumption

|

lit/min

|

10

|

|

Permanent sound - pressure level

|

dB (A)

|

< 70

|

|

Programs

F1 Coating 5 free programs

F2 Coating heating/drying 5 free programs

F3 Building-up of layer 5 free programs

Option R

■ Cleaning of the coating edge by means of moistened wiping-off rolls. The wiping-off rolls are washed out automatically. The wiping process after coating is actuated by an electric motor.

Option T

■ Intermediate drying of the layer by means of hot air from the printing side. This allows to build up a layer on the printing side by alternating between coating, drying and coating processes, etc. The speed of the hot air drying and the number of drying moves are programmable.

Option P

■ If required, the data can be printed out on reel paper after each program end.

Option Z

■ Multiple reception of several screen frames by means of additional pneumatic screen frame clamping device on top and at the bottom. The left and right side can be separately controlled via a foot-operated pedal.

Previous Page | Back | Next Page