Stencil Making Equipments

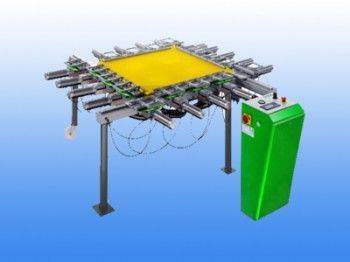

G-Stretch 281B

The G-STRETCH 281 BASIC enables you to reduce mesh costs, to stretch with utmost speed and flexibility while keeping expenses under control

Particular features

■ High degree of productivity, low consumption of mesh- saves up to 10% of the mesh costs.

■ Ideal for stretching large-size screens or for simultaneous treatment of several smaller formats.

■ Optimal handling and highest possible stretching precision.

■ The mesh can be stretched from four sides.

■ No contact between the mesh and the frame during the stretching process. As soon as the mesh has reached the final stretching value, the table can be lifted and the screen approaches the mesh from below.

■ Progressively adjustable stretching speeds.

■ Uncomplicated adjustment of the desired stretching angle.

■ All the end positions of the stretching beams are protected by means of limit stop switches.

■ The DUPLEX stretching clamps G-STRETCH 201 are equipped with concave ball bearings running in high-precision guide shafts made of stainless steel. During the stretching process, the clamps are capable of lateral shifting, in order to compensate the mesh extension.

■ The width of a stretching clamp is 250 mm/10“. Thanks to this ideal width, any irregularities of the mesh are automatically compensated by every individual stretching clamp.

■ Rugged and long-lasting steel construction.

|

Screen format

|

SB stretching width

|

mm

|

1500-4000

|

|

.

|

.

|

inch

|

59"-157"

|

|

.

|

SL stretching length

|

mm

|

2000-10000

|

|

.

|

.

|

inch

|

79"-394"

|

|

.

|

Profile thickness

|

mm

|

30-120/1"-5"

|

|

Options

|

F.R.W.N. G-STRETCH 208P

|

||

|

Overall sizes

|

Total width

|

SB+ 810/32"

|

|

|

.

|

Total length

|

SL+1415/56"

|

|

|

.

|

Total height

|

1040/41"

|

|

|

Electric power supply

|

V

|

1x230+N+PE

|

|

|

.

|

.

|

.

|

3x220+PE

|

|

.

|

Fuse protection

|

A

|

10

|

|

.

|

Power

|

kW

|

2

|

|

.

|

Frequency

|

Hz

|

50/60

|

|

Permanent sound pressure level

|

dB (A)

|

< 70

|

|

|

Varnish

|

Pantone 354C/425C

|

.

|

|

Option F

■ Wire-less remote control for all the functions.

Option R

■ The mesh reel holder facilitates the mesh insertion prior to the stretching process.

Option W

■ The angular stop piece allows an uncomplicated adjustment of various screen angles

Option N

■ The mesh holding-down device ensures that the mesh is in perfect contact with the screen frame, so that it can be faultlessly glued.

Option G-STRETCH 208P

■ The pneumatic pre-stressing device can be applied directly on the stretching machine in order to achieve a pneumatic pre-stressing of large-size screens. After the mesh has been glued onto the frame, this guarantees a considerable reduction of the tension loss. The pre-stressing device can be shifted lengthwise and in the stretching angle. The width can be progressively adjusted to the screens.

Previous Page | Back | Next Page