Stencil Making Equipments

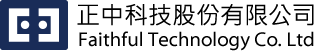

G-Coat 420

The G-COAT 420 is a coating machine for large-size meshes without compro- mising quality, in a fully automatic and safe manner

Particular features

■ Unique and extremely rugged construction with special aluminum profiles. Simple loading possible from both sides, reduced loading height. Optimal choice for large-size formats with a maximum width of 7000 mm and height of 9000 mm.

■ The patented coating head allows an optimal contact pressure at the center of the screen and guarantees a regular build-up of the layer even in the event of large screens

■ Drive unit with toothed belt requiring only a minimum of maintenance, with guide profiles of special synthetic material.

■ Length measuring system for all drive units. Programmable upper frame holder for the desired frame height. Upon pressing a button, the coating troughs move to the optimal filling position.

■ The frame height, the screen frame profile height and the wiping height of the layer can be individually programmed. The wiping height of the coating troughs is automatically offset.

■ The separate actuation of both coating troughs allows to coat the mesh from the squeegee side, from the print side or from both sides. Highest possible reproducibility of the coating results (tolerance +/- 1μ).

■ Extremely torsion-free trough supporting profiles with pre-stressing mechanism.

■ Programmable trough contact pressure for the coating process.

■ Pneumatic clamping units on top and at the bottom for an optimal fastening of the screen frames. The stretching units can be laterally adapted to the desired frame size. For increased machine widths, additional clamping units are installed. The clamping units are controlled via a foot-operated pedal.

■ Extremely robust screen frame reception unit with special profiles and integrated sliding bands.

|

Screen frame size

|

SB Screen frame width

|

mm

|

1500-7000

|

|

|

|

inch

|

59-275.6"

|

|

|

SH Screen frame height

|

mm

|

1250-9000

|

|

|

|

inch

|

49.2-354.3"

|

|

|

Frame profile height

|

mm/inch

|

40-200/1.5-7.9"

|

|

|

Frame profile thickness

|

mm/inch

|

10-60/0.4-2.3"

|

|

Index of options

|

R.T.Z

|

|

|

|

Overall size

|

Total width

|

mm/inch

|

SB+ 440/17.3"

|

|

|

Total height

|

mm/inch

|

SH+ 950/37.4"

|

|

|

Total depth

|

mm/inch

|

1325/52"

|

|

Energy supply

|

Nominal voltage Volt

|

V

|

3x400+N+PE

|

|

(Depending on the heating capacity)

|

3x220 + PE

|

||

|

|

Fuse protection

|

A

|

10-25

|

|

|

Capacity

|

kW

|

1.5-12

|

|

|

Frequency

|

Hz

|

50/60

|

|

Compressed air

|

Connection value

|

bar

|

7

|

|

|

Air consumption

|

lit/min

|

10

|

Programs

50 coating programs

50 screen frame programs

Option R

■ Automatic cleaning of the coating edges: on both sides, the remaining emulsion is wiped off with moistened wiper rolls. The wiper rolls are automatically moistened and washed out. They are automatically turned after one pass.

Option T

■ Automatic hot-air dryer with temperature regulator and a frequency-controlled drive unit. This device is used for intermediate drying between individual layers or for the final drying of a screen. It is important to note that the drying process is carried out from the print side, independently from the coating carriage. The drying speed and the number of moves can be programmed.

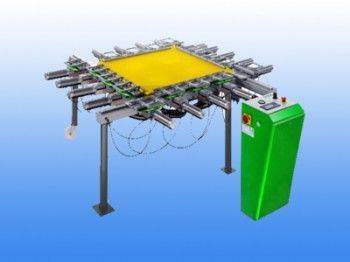

Option Z

■ Simultaneous coating of two adjacent screen frames.

Previous Page | Back | Next Page